Custom Paper Packaging Manufacturer in China

Custom Boxes and Packaging for differerent Industries

Elevating Brands with Exquisite Packaging Solution

20 Years Serving

Europen and American Market

Partner with Luxury Brands

Hundreds of Classic Cases for reference

Lower MOQ, More Flexibility

Get Factory Price Start From 500PCS

Certification

ISO9001, ISO14001, SEDEX, FSC

What We Produce

Exceptional Custom Boxes and Packaging. Located in China, we merge our deep-rooted craftsmanship with advanced technology to create packaging solutions that are both stylish and durable.

About Us

Welcome to Xiamen Chief Color Co., Ltd, a luxury paper packaging manufacturer in China. Over the past 19 years, we have evolved from a small workshop into a modern enterprise equipped with advanced machinery and staffed by skilled professionals.

20 Years Experience in manufacturing and exporting

108 Workers, Monthly capacity- 700K rigid box, 1400K prestigage paper bags

Certification:

ISO9001, ISO14001, SEDEX, FSC and invent patents

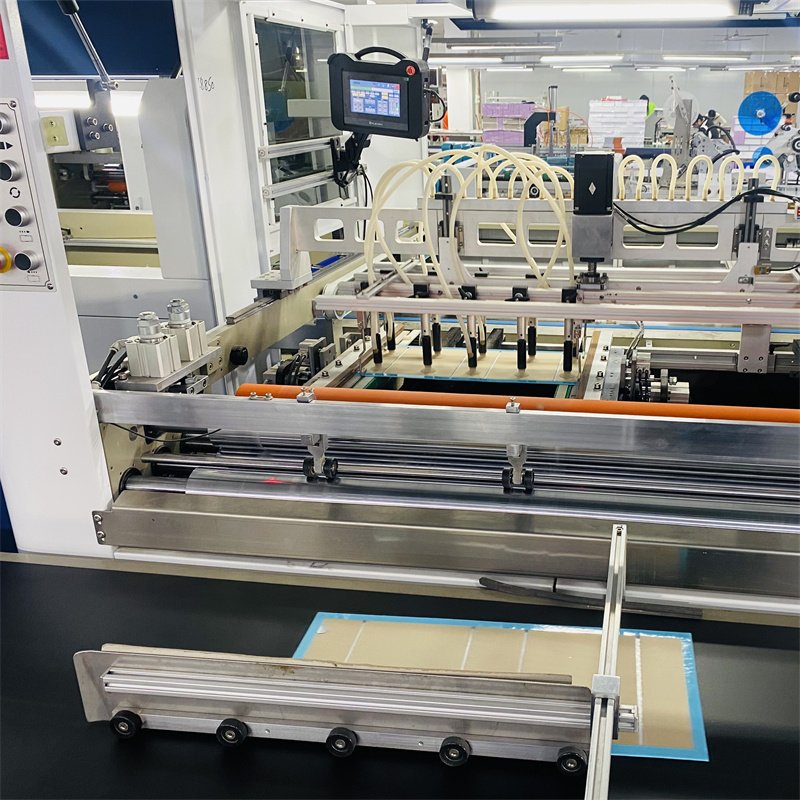

Top Manufacturing Equipments, full aotumatic production lines

Why Choose Us

As a top packaging manufacturer in China, we continually innovate to stay ahead of global trends and meet customer expectations. Each box we create reflects our dedication and commitment to delivering the highest quality custom boxes and packaging.

Self-owned Heidelberg Printer

Highly Efficient Equipment for Rigid Box Manufacturing

Coalition of well trained manual workers and advanced machine

Your one-stop supplier of paper packaging solutions

Free White Sample Developing

Custom Packaging Solutions for Various Industries

As a top gift box factory and rigid box manufacturer in China, we specialize in creating bespoke packaging that elevates your products’ value. Our commitment to producing premium custom boxes and packaging caters to a diverse array of industries worldwide.

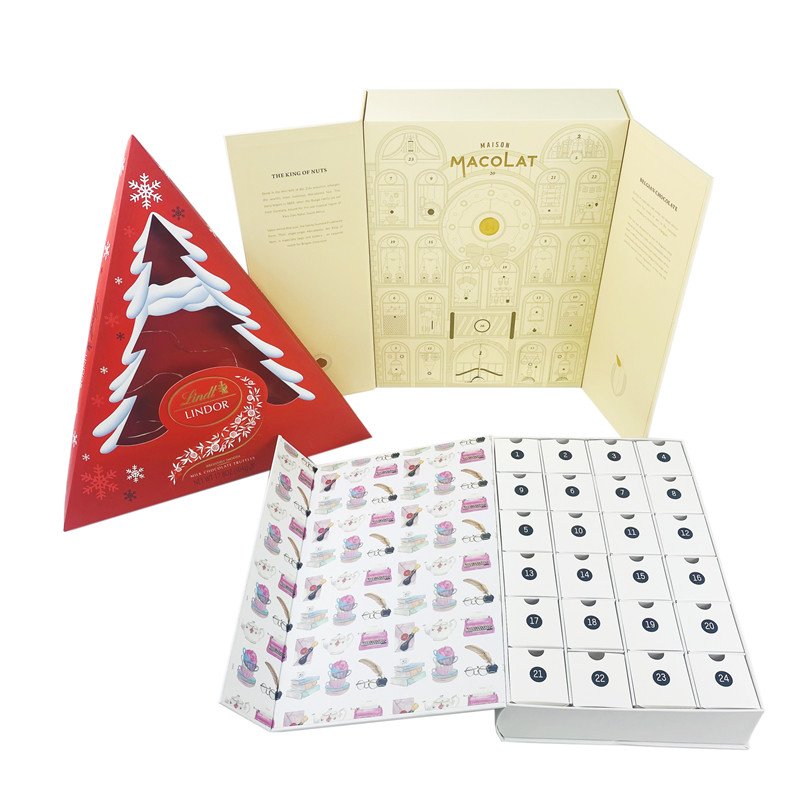

Chocolate and Bakery Packaging

Cosmetic and Skincare Packaging

Candle and Diffuser Packaging

Advent Caldendar Packaging

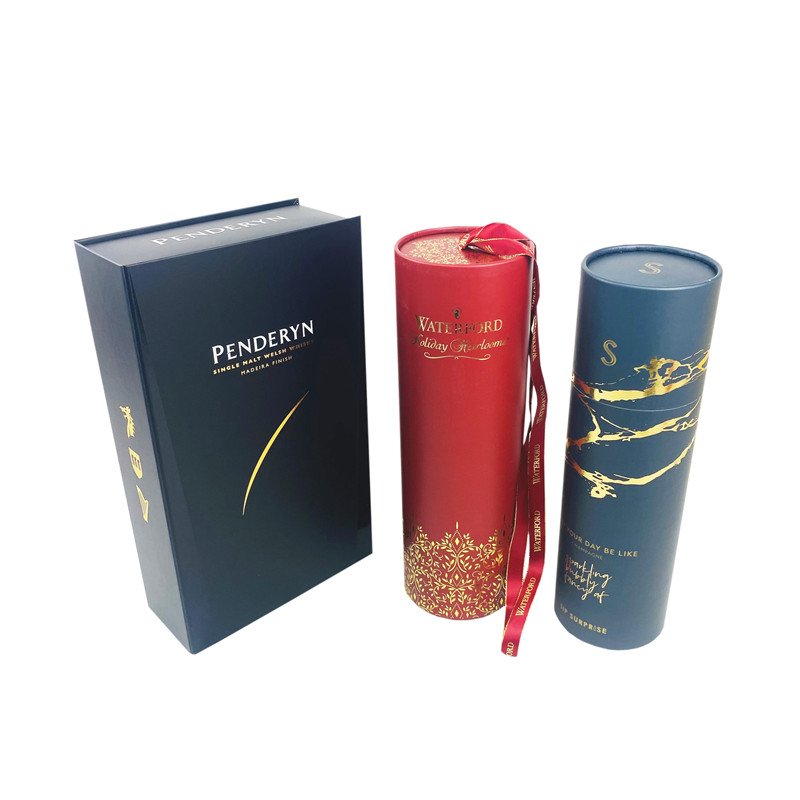

Wine Packaging

Jewellery Packaging

Flower and Gift Packaging

E-commerce Packaging

We are here at your disposal for any technical or commercial information

Creating Custom Boxes and Packaging

Take a visual tour of Chief Color’s state-of-the-art production line for luxury gift boxes. As a premier gift box manufacturer in China, we are proud of our meticulous craftsmanship and attention to detail. Our videos reveal the artistry behind our branded paper packaging, showcasing everything from the selection of high-quality materials to the final elegant touches.

Playlist

Customize Your Packaging Now!

Gift Box China – Reflecting Your Brand’s Essence

From paper shopping bags to custom gift boxes, our range is designed to meet the diverse needs of various industries. Our specialization in custom boxes and packaging allows us to tailor every detail to your specific needs, ensuring a perfect match for your products.

FAQ

If you are new to custom product packaging, please be patient and read below FAQ for a clear understanding of our services and the value we can add to your packaging needs. While every customer have different requirement for customized boxes and bags for products, we are all ears for your questions, consults and inquiries.

We specialize in producing high-end custom paper packaging products, including custom gift boxes, paper shopping bags, and cartons. Our products are tailored to meet the diverse needs of our clients, whether for retail packaging, promotional events, or special occasions.

To get a quote for your custom packaging, simply follow these steps:

- Step 1: Provide us with your packaging requirements, including the product details, preferred materials, design specifications, and quantity.

- Step 2: If you have any reference images or examples, feel free to share them.

- Step 3: Our team will review the information and send you a detailed quote based on your needs.

You can submit your request through our contact form on the website, by email to info@chiefcolor.com, or by phone +86 592-5691077. We’re happy to assist you every step of the way.

We provide a variety of printing options such as offset, silk-screen, and digital printing to achieve superior quality and branding consistency. Options include embossing, foil stamping, and UV coating to enhance the custom business packaging’s visual appeal and tactile quality.

Quality assurance is one of the most important part to our process. We conduct rigorous quality checks at multiple stages of production to ensure every custom packaging box and bag meets our high standards. Additionally, our production processes are ISO certified, reflecting our commitment to quality and consistency.

We offer eco-friendly packaging solutions, including recycled materials and biodegradable options. Our team is committed to providing sustainable choices without compromising on quality, helping brands stay aligned with their environmental values.

Our minimum order quantity depends on the specific product and customization details. Typically, it starts at 1000 pieces for more customized orders. This quantity ensures cost-effectiveness while allowing for high-quality production standards.

Once custom design specifications are finalized, it regularly takes about 7-10 days to produce and ship a sample. This time frame allows us to ensure that every detail meets your expectations before proceeding with the full order.

Production lead times vary based on order size and customization details, generally ranging from 15 to 30 days. Delivery times depend on the destination country but are typically between 6 to 8 weeks from China to Europe. Expedited options are available upon request.

We manage all aspects of shipping and logistics to ensure a smooth delivery process. Our logistics team works with reliable carriers to offer cost-effective and timely shipping solutions across major developed countries in Europe and the U.S.. We can also recommend you the forwarders that we used if you want to figure out the shipping cost by yourself while you don’t have any forwarder contact. As it is believed that it is more benefit for buyer to get shipping cost.

We provide comprehensive support to all clients, especially those new to custom packaging. Our team guides you through every step, from design selection and material choice to final production, ensuring a seamless experience and a product that perfectly suits your needs.

Blog

How Post-Consumer Waste (PCW) Packaging Benefits Your Business and the Environment

As someone with years of experience in paper packaging, I’ve always looked for ways to make packaging more sustainable without compromising on quality. One of

Mooncake packaging plays an important role on mid-autumn festival

The Mid-Autumn Festival, celebrated in many East Asian cultures, is a time of family reunions, moon-gazing, and enjoying traditional delicacies, with mooncakes being one of

Are Paper Boxes Microwave Safe?

As one of the experienced packaging consultant from Chiefcolor, a leading manufacturer of custom printed paper boxes and bags, I’ve often encountered the question: Are paper boxes microwavable?

Table of Contents

Your Ultimate Guide to Acquiring Custom Boxes and Packaging

Welcome to your definitive resource for all things custom boxes and packaging! At Xiamen Chief Color Co.,Ltd, we specialize in manufacturing custom printed, branded paper packaging that elevates your products and enhances your brand image. Located in the heart of China, our factory is dedicated to producing luxury gift boxes and paper shopping bags tailored to meet the diverse needs of industries worldwide.

Explore our comprehensive guide to discover how custom boxes and packaging can transform your product presentation and drive business success. Let us help you create packaging that not only protects but also promotes your products, making them stand out in a competitive market.

Experience why businesses worldwide trust Xiamen Chief Color for their packaging needs. Discover how our high-quality, custom packaging can make a real difference for your brand.

Chapter 1

Customized Paper Bags: A Complete Guide to Quality and Flexibility

How to Customize the Ideal Paper Bag for Your Needs

Selecting the perfect paper bag involves understanding various aspects of its production, design, and functionality. A carefully crafted bag can enhance your product presentation while supporting your sustainability goals. Below is a comprehensive guide to help you make the right choice:

1. The Paper Bag Manufacturing Process

A high-quality paper bag begins with a well-controlled manufacturing process. Reputable manufacturers use advanced equipment and sustainable materials to ensure the bags maintain consistent strength, durability, and aesthetic appeal. While some larger bags, particularly premium ones, may involve more manual assembly, this adds a personal touch and ensures craftsmanship.

2. Choosing the Right Material

The material of the paper bag plays a critical role in its durability, environmental impact, and suitability for specific purposes. Popular options include:

Kraft Paper: Known for its strength and rustic look, ideal for eco-conscious brands.

Recycled Paper: A sustainable choice that reduces environmental impact without compromising on strength.

Laminated Paper: Offers a premium finish and greater durability, often used for high-end products.

3. Customizing Size and Style

Paper bags are highly customizable. When selecting the size and style, consider the purpose of the bag and the items it will carry. Options include:

Standard Paper Bags with Handles: Ideal for everyday use, retail packaging, or takeout bags.

Laminated Paper Bags: Suitable for luxury items or high-end retail, offering a polished, professional appearance.

Paper Carrier Bags: Great for groceries, books, or other heavier products, often with additional reinforcements to support weight.

4. Printing and Branding

Custom printing transforms a simple paper bag into a powerful branding tool. High-quality printing techniques, such as offset or flexographic printing, ensure your logo, design, or messaging stands out. When possible, choose eco-friendly inks for a greener impact. This enhances your brand identity and communicates your company’s values.

5. Durability and Load-Bearing Capacity

The strength of your paper bag is crucial to its functionality. To improve durability and load-bearing capacity, consider:

- Reinforced Handles: Ensure the bag is comfortable and sturdy for customers to carry.

- Gusseted Sides: Allow the bag to expand and fit larger or bulkier items.

- Multi-Layer Construction: For additional support, especially in bags intended to carry heavier products.

6. Sustainability in Paper Bag Manufacturing

As sustainability becomes increasingly important, eco-friendly paper bags are a top choice for businesses aiming to reduce their environmental footprint. Look for bags made from:

- Biodegradable Materials: Easily break down without harming the environment.

- Recyclable Paper: Can be reused and repurposed, contributing to a circular economy.

If you’re interested in Post-Consumer Waste (PCW) materials, please check our article for more detailed information on the benefits and options available. Click and check “How PCW Packaging Benefits Your Business And The Environment“

7. Balancing Cost and Quality

While budget is always a consideration, it’s essential to balance cost with quality and durability. A well-crafted paper bag may come at a slightly higher price, but its long-term performance can provide better value. This is especially important for luxury or high-end packaging, where the appearance and durability of the bag directly affect your brand’s image.

8. Finding a Reliable Paper Bag Manufacturer

Partnering with an experienced paper bag manufacturer ensures consistent quality and access to a range of customization options tailored to your specific needs. Look for manufacturers with a track record of delivering high-quality products on time, and who are experts in optimizing the design and production process to meet your business goals.

By focusing on these key factors, you can select paper shopping bags that are not only functional and stylish but also align with your environmental and brand objectives. Reach out to us today to explore our range of paper bag solutions and discover how we can support your packaging needs effectively.

Every Bag Tells a Story – Let Yours Be Memorable!

Chapter 2

Full Specifications and Customization Options for Paper Carrier Bags

When it comes to creating the perfect paper shopping bag, the specifications matter. From the choice of paper material to the finishing touches like handles and printing, every detail plays a role in both the bag’s functionality and its ability to represent your brand. Below, we outline the key specifications that can be customized to suit your needs, ensuring you get the ideal paper carrier bag for your products.

Full Specification of a custom paper carrier bag:

| Material Types | White Kraft paper Natural Kraft paper Coated paper (C1S) Art paper (C2S) Dyed paper Corrugated paper |

| Grammage (GSM) | Lightweight: 60-80 GSM (for small bags) Medium: 100-150 GSM (for moderate loads) Heavy-duty: 200-300 GSM (for heavy or bulky items) |

| Size and Dimensions | Customized to fit products (e.g., 10×15 cm, 20×30 cm, etc.) Dimensions include: Height x Width x Gusset (side or bottom fold for expansion) |

| Carrying Capacity | Weight-bearing capacity ranges from 1 kg to 25 kg. Reinforcement features (e.g., thicker handles, extra layers of reinforcement cards) can increase capacity. |

| Handles Types | Flat paper handles Twisted paper handles Die-cut handles Rope or string handles Material: Paper, Cotton, PP, Nylon or synthetic fiber. |

| Printing and Branding | Printing techniques: Flexographic Offset Digital Number of colors supported (e.g., CMYK, Pantone) Eco-friendly inks (water-based or soy-based) |

| Lamination and Coating | Glossy lamination Matte lamination PE coating (for moisture resistance) Uncoated for eco-friendliness. |

| Special Features | Tear resistance (reinforced paper or added fibers). Water resistance (waxed or coated layers). Ventilation holes (e.g., for food or produce bags). Food-grade certifications for direct food contact. |

| Environmental Compliance | Biodegradable: Decomposes naturally. Recyclable: Made from and suitable for recycling. Certifications: FSC (Forest Stewardship Council) ISO standards for environmental safety. |

| Additional Features | Window cutouts (plastic-free film or open). Foldable design for easy storage. String or ribbon closures for luxury bags. |

Chapter 3

How Are Rigid Boxes Manufactured?

Every custom box and packaging is a display of art and wit, carefully designed to not only protect but also showcase your product in the best light. As one of the leading rigid boxes suppliers, we pride ourselves on our careful-planned manufacturing process, ensuring every box meets the highest standards of craftsmanship. In this chapter, we’ll walk you through the step-by-step procedure of how rigid boxes are made, from design to production, highlighting the expertise and precision involved. Whether you’re a retailer, brand, or print and packaging company, understanding the creation of custom rigid boxes is key to appreciating the value and durability they bring to your products.

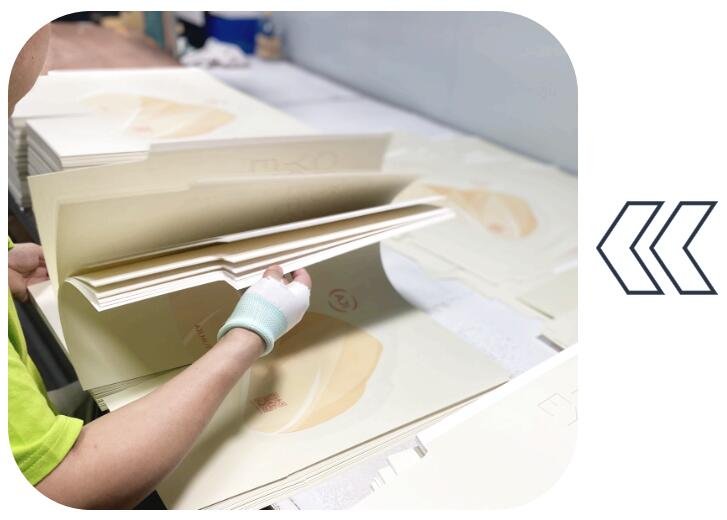

Our Custom Wrapping Paper Preparing Process

Printing

Print designs or patterns onto the wrapping paper.Finishing

Apply surface treatments like glossy, matt lamination, embossing and debossing, hot foil stamping, or Spot UV.Die-cut

Die-cut the paper to shape it into the required size.IPQC – In-Process Quality Check

IPQC is a non-negotiable requirement between every 2 processes.

Our Rigid Cardboard Preparing Process:

Cutting and Shaping

Cut the greyboard into the required size and shape with precision.V-groove and Die-cutting

Use a die-cutting machine to shape the greyboard.

Cut U-grooves or V-grooves into the greyboard for cleaner and more precise folding edges as per design requirements.Applying Magnets and Fitments

Attach magnets and iron plates to the pre-cut greyboard for magnetic box styles.

Apply PVC films and ribbons before wrapping the liner material.

Laminating the custom wraps onto the rigid cardboard

Forming ➡️ Wrapping ➡️ Assembling

Chapter 4

6 Essential Rigid Box Styles to Elevate Your Custom Packaging

When it comes to custom boxes and packaging, rigid boxes stand out as the ultimate choice for premium products. Known for their durability, elegance, and versatility, rigid boxes offer unparalleled support and visual appeal, making them a staple in luxury box packaging. Whether you’re showcasing high-end goods or aiming to elevate your brand’s packaging and labeling, choosing the right rigid box style is key.

Below, we explore six popular rigid box styles, each designed to cater to specific needs while enhancing the unboxing experience. From timeless classics to innovative constructions, these box types prove that functionality and aesthetics can go hand in hand.

1. Base and Lid / Lift-Off Lid Box Style

Functionality & Practicality: The base and lid or lift-off lid box style is a timeless packaging solution offering easy access and secure protection. The separate lid allows for a sleek, elegant opening experience, while the rigid construction provides durability to safeguard products.

Popular Usage: Often used in custom boxes and packaging for luxury items such as jewelry, high-end cosmetics, and gift sets. This style is perfect for retail and promotional packaging that requires a high-quality presentation and robust protection during shipping.

2. Hinged Lid Box

Functionality & Practicality: A hinged lid box is both functional and stylish, featuring a connected lid that opens like a book. The hinge mechanism allows for repeated use and easy access to the product, providing a premium unboxing experience. It is sturdy and compact, ensuring the product stays protected.

Popular Usage: Commonly used for custom packaging of watches, electronics, and luxury gifts. This design is ideal for items that require secure, long-term storage and frequent handling, while still maintaining a high-end look.

3. Slide Drawer Style Box

Functionality & Practicality: The slide drawer box is known for its unique pull-out design, offering a sleek, interactive experience. The smooth sliding mechanism ensures easy opening and closing, while the rigid structure provides excellent product protection. The drawer style adds an element of surprise and luxury.

Popular Usage: Ideal for luxury packaging, including perfume sets, cosmetics, and gift boxes. It’s also widely used for subscription boxes, collectibles, and other high-end retail items where presentation is key.

4. Tube Box / Cylinder Packaging Box

Functionality & Practicality: The tube box offers a unique cylindrical shape, perfect for products that need a snug fit, like bottles, cosmetics, or candles. The durable, rigid structure ensures the items inside are well-protected, while the eye-catching design makes it stand out on shelves or in-store displays.

Popular Usage: Tube boxes are commonly used for premium packaging of wine bottles, liquor, beauty products, and gift items. They’re an ideal choice for custom boxes and packaging when looking to create a distinctive, modern, and premium feel.

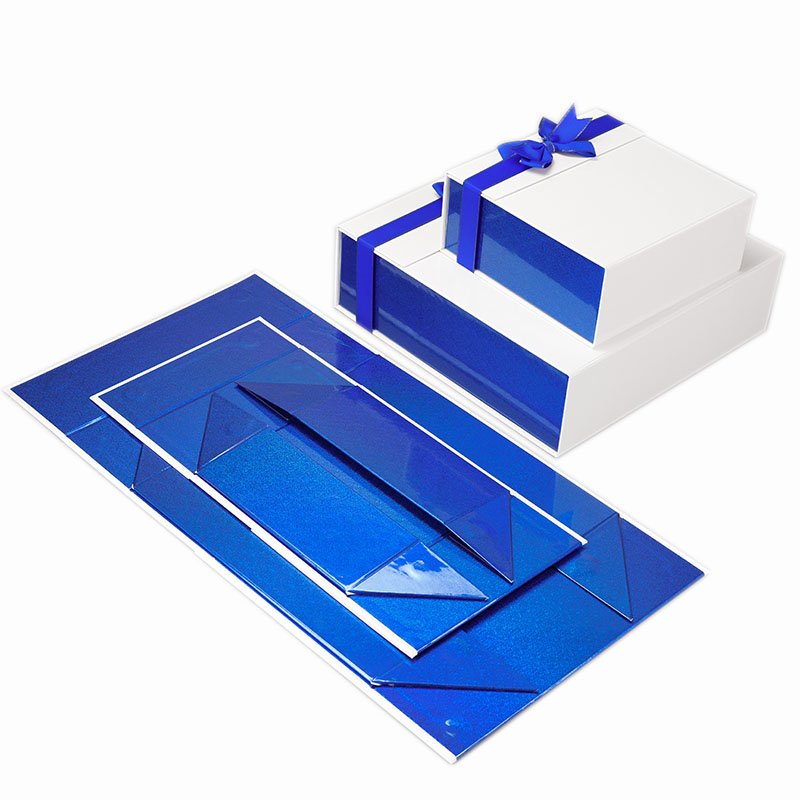

5. Wardrobe Style Box / Advent Calendar Boxes

- Functionality & Practicality:

The wardrobe-style box is a versatile packaging solution designed with a fold-out structure that mimics the functionality of a wardrobe. Its spacious interior makes it ideal for housing multiple compartments, making it perfect for products requiring organization or a sense of discovery. Often associated with advent calendar boxes, this style is popular for luxury packaging where presentation and practicality are key. Sturdy and durable, it ensures protection during shipping and enhances the unboxing experience. - Popular Usage:

This box style is frequently used in luxury box packaging for items like chocolates, cosmetics, and premium advent calendar sets, where multiple smaller products are beautifully arranged. It’s also a favorite for showcasing high-end gifts, promotional items, or specialty products that demand both elegance and functional appeal.

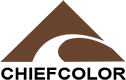

6. Foldable Rigid Boxes

- Functionality & Practicality: The flat-packed foldable box is a highly practical and space-saving solution. This style is designed to be easily assembled by the end user, and it can be flat-packed during shipping, reducing storage and transportation costs. Its sturdy construction ensures that it provides reliable protection for the product, even in its folded form.

- Popular Usage: This style is often used for retail packaging, e-commerce shipments, and promotional packaging. It’s a popular choice for brands looking to balance cost-effectiveness and customization, particularly for products like apparel, consumer electronics, and gift sets. The foldable design allows for efficient packing and minimal storage space, making it a great choice for businesses that require high-volume packaging solutions.

Customization Options

All of our rigid box styles are based on these standard designs, but we can adjust and modify them to suit your unique needs. Whether you’re looking for a heart-shaped, octagonal, hexagonal, or triangular box, we offer the flexibility to create packaging that matches your vision. Each box is carefully customized according to your product’s specific requirements, ensuring a perfect fit.

Additionally, we provide a range of accessories such as EVA foam, velvet sponges, blister trays, and paperboard seat cards to securely hold and protect your product. These components not only enhance the overall presentation but also offer added protection during transit. The materials for these accessories, as shown in the attached images, are selected to ensure both functionality and aesthetic appeal, giving your packaging a refined and professional look.

Chapter 5

Top Rated Collapsible Rigid Box Styles / Foldable Rigid Box Styles

As we discussed the Functionality & Practicality about the flat packed rigid box, the main function is save space while also keep the premium looking after it is set-up. We are proud to tell you that we can make any size of box to be collapsible. Let us know show you the essential styles of foldable rigid boxes which we can developed versatile construction by multiple elements. For example, on the way of closure, we can design it with ribbon closure and magnetic closure as well as eco-friendly cardboard tucked closure.

Style #1: Foldable Rigid Box with 4 corners adhesive tape

Chapter 6

High-Quality Paper Materials Suggestion for Custom Packaging

When creating custom packaging, the choice of paper material is one of the most important factors in conveying the quality and luxury of the product. Renowned paper brands such as Fedrigoni, Gruppo Cordenons, Favini, Colorplan, and Winter’s Company are popular choices for luxury and high-end packaging solutions due to their premium quality, unique textures, and range of colors. These brands are trusted by designers and packaging professionals to enhance product presentation and elevate brand image.

- Fedrigoni

A prestigious Italian brand, Fedrigoni is known for its high-quality paper that offers excellent printability and a luxurious finish. Their papers are often chosen for premium packaging, such as high-end cosmetics, luxury goods, and exclusive gift boxes. Fedrigoni’s extensive range includes unique finishes like textured, metallic, and natural paper, giving brands the opportunity to create distinctive, memorable packaging. - Gruppo Cordenons

Another Italian leader in the paper industry, Gruppo Cordenons specializes in fine papers used for premium packaging. They offer a broad selection of colors and textures, including their signature “Wild”collection, which features eco-friendly papers with a natural, handmade feel. Their papers are ideal for creating bespoke packaging that makes a statement in both design and environmental consciousness. - Favini

Favini is known for its eco-friendly and innovative paper solutions. Their papers are made using sustainable practices, and they offer unique materials such as “Shiro Alga Carta”—a paper made from algae waste—and “FSC-certified”papers. Favini’s commitment to sustainability makes it a great choice for brands that prioritize environmental responsibility while still wanting to achieve luxury packaging. - Colorplan

Produced by the UK-based G.F. Smith, Colorplan is a high-end, colored paper known for its rich texture and vibrant hues. With a range of 50 colors and several finishes, Colorplan allows for creative packaging designs that stand out. It’s often used in high-end retail packaging and luxury brand identity. - Winter’s Company

Winter’s Company is a premium paper manufacturer known for its eco-friendly credentials and exceptional quality. Their papers are often used in luxury packaging, offering a sophisticated look and feel, combined with sustainability. The brand’s papers are perfect for high-end retail brands seeking an elegant and environmentally-conscious packaging solution.

Alternative Paper Materials for Budget-Conscious Clients: Mimicking Luxury with Art Paper and White Kraft Paper

For brands that want to achieve the look and feel of premium packaging without the high costs associated with luxury papers, regular art paper and white kraft paper can be excellent alternatives. Through various techniques such as embossing, debossing, and printing, these more affordable materials can be transformed to replicate the textures, colors, and sophistication of higher-end papers.

- Mimicking Texture with Embossing and Debossing

One of the most effective ways to replicate the tactile quality of luxury paper is through embossingand debossing. These techniques involve creating raised or recessed designs on the paper surface, which can mimic the textured feel of high-end papers like those from Fedrigoni or Gruppo Cordenons.

- Embossingcreates a raised effect, perfect for logos, patterns, or unique design elements, giving a sense of depth and luxury.

- Debossingcreates a sunken effect, which can be used for more subtle, elegant textures that are often seen in premium packaging.

Both techniques can be applied to regular art paper or white kraft paper, allowing brands to achieve a rich, tactile quality without the premium price tag.

- Printing to Replicate Premium Color and Detail

While art papers and kraft papers may not have the same depth of color and finish as high-end options like Colorplanor Favini, they can still be enhanced with high-quality printingto mimic vibrant, custom colors. Digital printing, offset printing, or spot color printing can add richness and precision to the paper, enabling brands to achieve vibrant colors, intricate patterns, and even metallic effects.

- Spot color printingcan be used to achieve specific hues that replicate the colorful vibrancy of premium papers, like those from Colorplan.

- Metallic printingor foil stamping can replicate the shimmering or glossy finishes found in luxury packaging, helping create a high-end feel.

For instance, white kraft paper, which is generally more rustic in appearance, can be printed with intricate designs to achieve a sophisticated, high-quality look. When combined with embossing, this creates a compelling visual and tactile contrast that mimics expensive, textured papers.

- Combining Both Techniques for Cost-Effective Luxury

By combining embossing or debossing with custom printing, brands can achieve a premium packaging design at a fraction of the cost. For example, a kraft paper boxcan be embossed with a textured pattern, then printed with a metallic logo or brand name, giving the appearance of a luxury packaging solution. This combination allows you to replicate the elegance and distinctiveness of premium papers without the associated costs.

Get A Free Quote

Contact us to get a free quote and more expertise about custom boxes and packaging. Your project will meet a right solution with Chiefcolor.

Boost Your Business with Custom Boxes and Packaging

Tell Us What You Need

Tell us as specific as possible of your needs, provide the drawing, reference picture and share your idea.

Get Solution & Quote

We will work on the best solution according to your requirement and drawing, the specific quote will be provided within 24 hours.

Sample & Mock Up

We will offer free white sample for testing and developing on your project.