Custom Paper Packaging Manufacturer in China

Custom Boxes and Packaging for differerent Industries

Elevating Brands with Exquisite Packaging Solution

19 Years Serving

Europen and American Market

Partner with Luxury Brands

Hundreds of Classic Cases for reference

Lower MOQ, More Flexibility

Get Factory Price Start From 500PCS

Certification

ISO9001, ISO14001, SEDEX, FSC

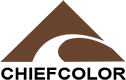

What We Produce

Exceptional Custom Boxes and Packaging. Located in China, we merge our deep-rooted craftsmanship with advanced technology to create packaging solutions that are both stylish and durable.

About Us

Welcome to Xiamen Chief Color Co., Ltd, a luxury paper packaging manufacturer in China. Over the past 19 years, we have evolved from a small workshop into a modern enterprise equipped with advanced machinery and staffed by skilled professionals.

19 Years Experience in manufacturing and exporting

108 Workers, Monthly capacity- 700K rigid box, 1400K prestigage paper bags

Certification:

ISO9001, ISO14001, SEDEX, FSC and invent patents

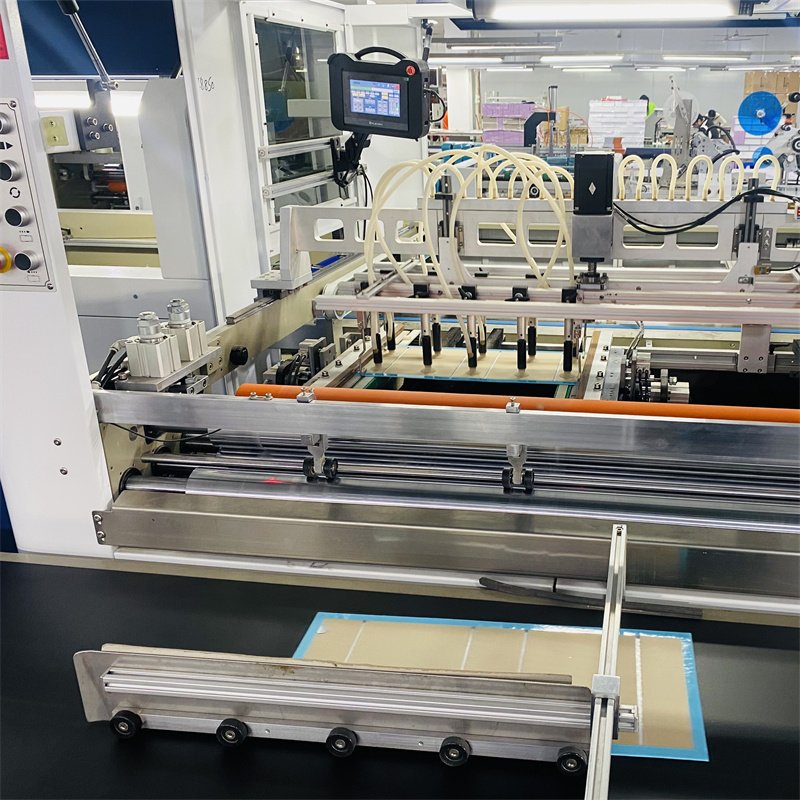

Top Manufacturing Equipments, full aotumatic production lines

Why Choose Us

As a top packaging manufacturer in China, we continually innovate to stay ahead of global trends and meet customer expectations. Each box we create reflects our dedication and commitment to delivering the highest quality custom boxes and packaging.

Self-owned Heidelberg Printer

Highly Efficient Equipment for Rigid Box Manufacturing

Coalition of well trained manual workers and advanced machine

Your one-stop supplier of paper packaging solutions

Free White Sample Developing

Custom Packaging Solutions for Various Industries

As a top gift box factory and rigid box manufacturer in China, we specialize in creating bespoke packaging that elevates your products’ value. Our commitment to producing premium custom boxes and packaging caters to a diverse array of industries worldwide.

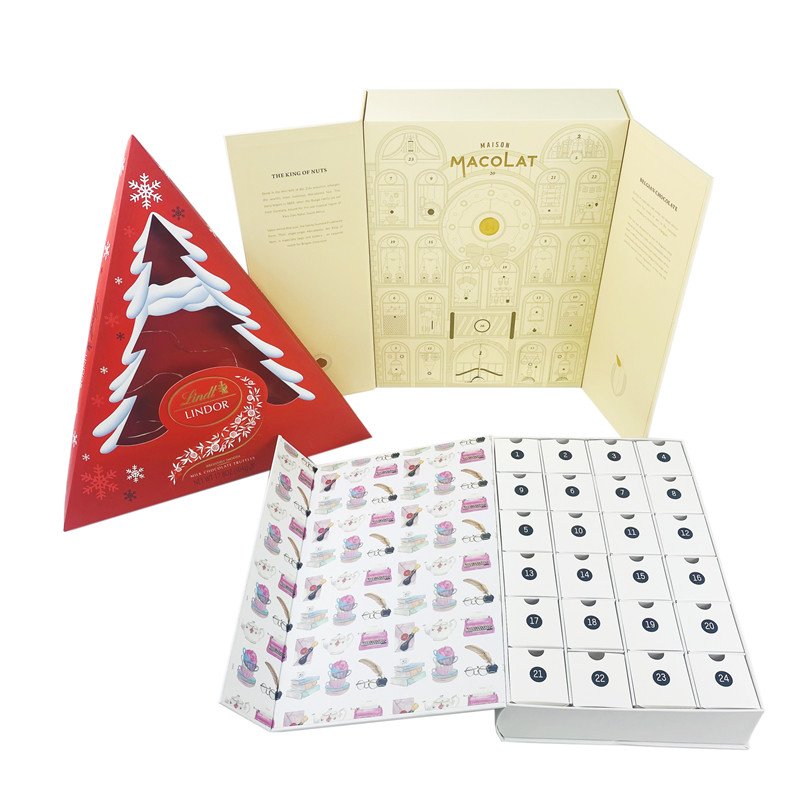

Chocolate and Bakery Packaging

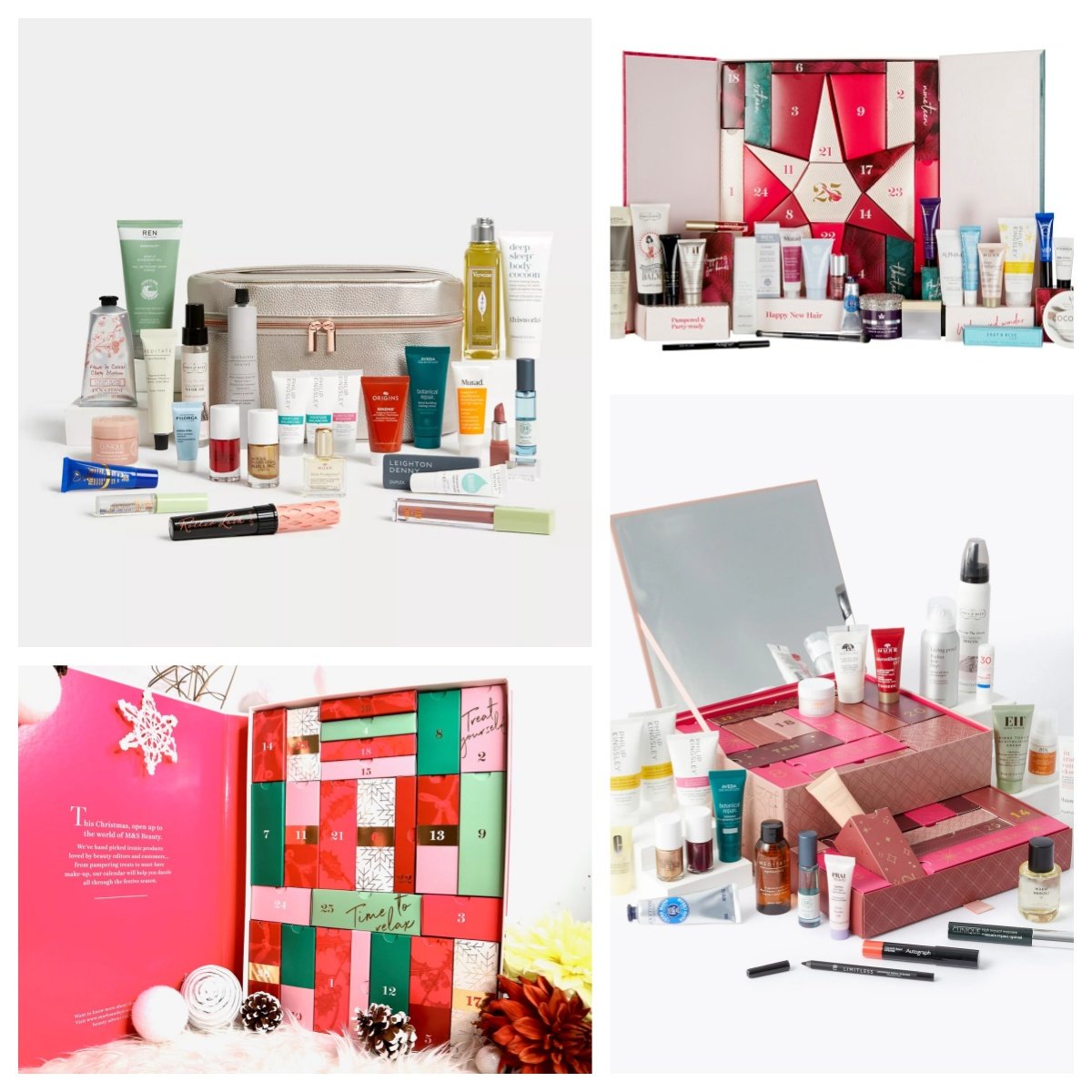

Cosmetic and Skincare Packaging

Candle and Diffuser Packaging

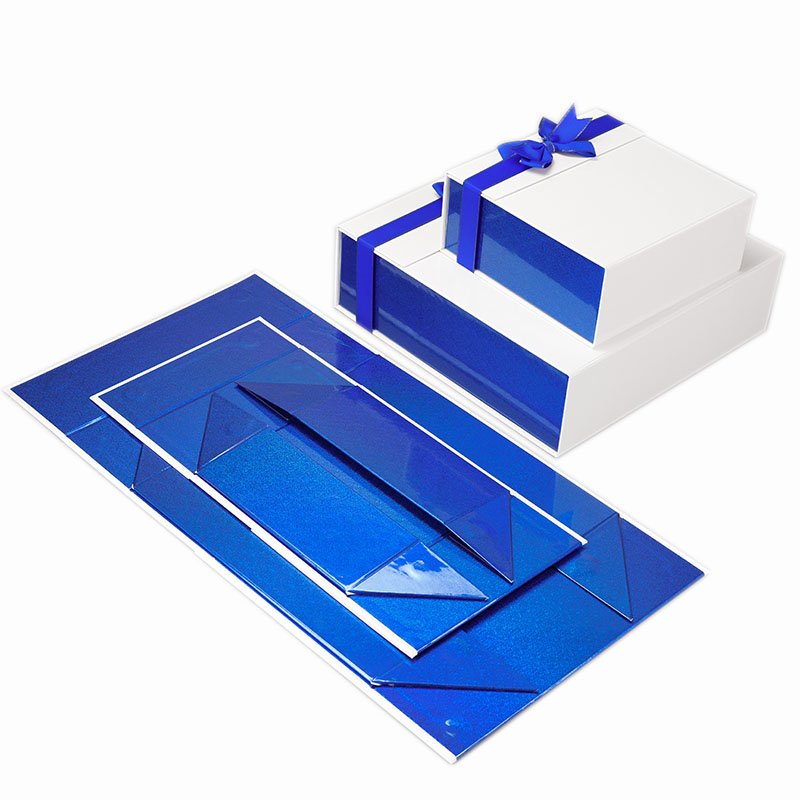

Advent Caldendar Packaging

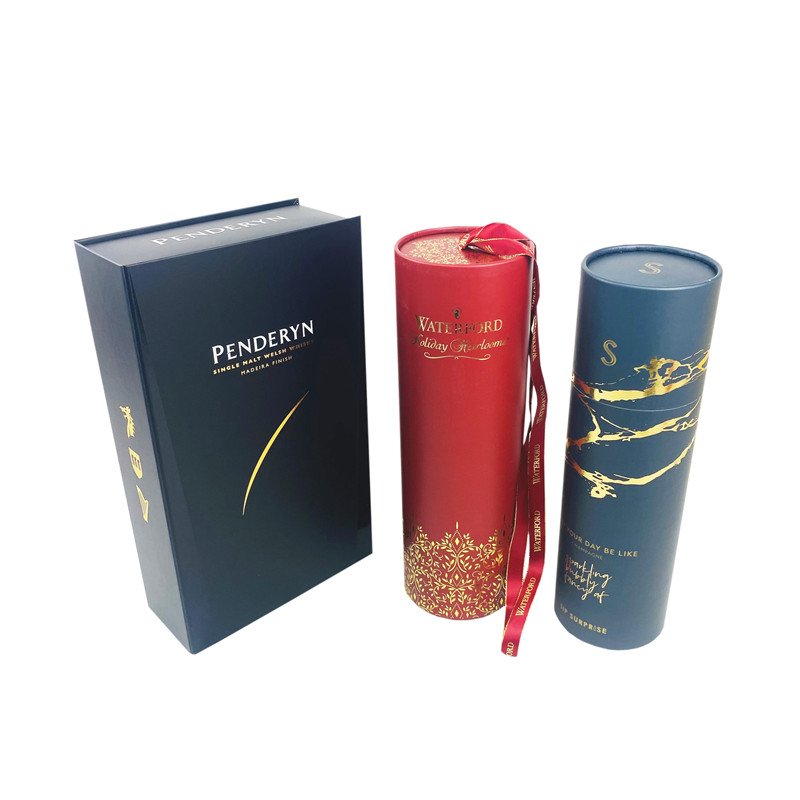

Wine Packaging

Jewellery Packaging

Flower and Gift Packaging

E-commerce Packaging

We are here at your disposal for any technical or commercial information

Creating Custom Boxes and Packaging

Take a visual tour of Chief Color’s state-of-the-art production line for luxury gift boxes. As a premier gift box manufacturer in China, we are proud of our meticulous craftsmanship and attention to detail. Our videos reveal the artistry behind our branded paper packaging, showcasing everything from the selection of high-quality materials to the final elegant touches.

Playlist

Customize Your Packaging Now!

Gift Box China – Reflecting Your Brand’s Essence

From paper shopping bags to custom gift boxes, our range is designed to meet the diverse needs of various industries. Our specialization in custom boxes and packaging allows us to tailor every detail to your specific needs, ensuring a perfect match for your products.

FAQ

If you are new to custom product packaging, please be patient and read below FAQ for a clear understanding of our services and the value we can add to your packaging needs. While every customer have different requirement for customized boxes and bags for products, we are all ears for your questions, consults and inquiries.

We specialize in producing high-end custom paper packaging products, including custom gift boxes, paper shopping bags, and cartons. Our products are tailored to meet the diverse needs of our clients, whether for retail packaging, promotional events, or special occasions.

Absolutely! We offer fully customizable packaging solutions. Clients can choose the dimensions, materials, design elements, and finishes for their business packaging. Our team collaborates closely with each client to ensure the final product reflects their brand’s aesthetics and requirements.

We provide a variety of printing options such as offset, silk-screen, and digital printing to achieve superior quality and branding consistency. Options include embossing, foil stamping, and UV coating to enhance the custom business packaging’s visual appeal and tactile quality.

Quality assurance is one of the most important part to our process. We conduct rigorous quality checks at multiple stages of production to ensure every custom packaging box and bag meets our high standards. Additionally, our production processes are ISO certified, reflecting our commitment to quality and consistency.

We offer eco-friendly packaging solutions, including recycled materials and biodegradable options. Our team is committed to providing sustainable choices without compromising on quality, helping brands stay aligned with their environmental values.

Our minimum order quantity depends on the specific product and customization details. Typically, it starts at 1000 pieces for more customized orders. This quantity ensures cost-effectiveness while allowing for high-quality production standards.

Once custom design specifications are finalized, it regularly takes about 7-10 days to produce and ship a sample. This time frame allows us to ensure that every detail meets your expectations before proceeding with the full order.

Production lead times vary based on order size and customization details, generally ranging from 15 to 30 days. Delivery times depend on the destination country but are typically between 6 to 8 weeks from China to Europe. Expedited options are available upon request.

We manage all aspects of shipping and logistics to ensure a smooth delivery process. Our logistics team works with reliable carriers to offer cost-effective and timely shipping solutions across major developed countries in Europe and the U.S.. We can also recommend you the forwarders that we used if you want to figure out the shipping cost by yourself while you don’t have any forwarder contact. As it is believed that it is more benefit for buyer to get shipping cost.

We provide comprehensive support to all clients, especially those new to custom packaging. Our team guides you through every step, from design selection and material choice to final production, ensuring a seamless experience and a product that perfectly suits your needs.

Blog

Mooncake packaging plays an important role on mid-autumn festival

The Mid-Autumn Festival, celebrated in many East Asian cultures, is a time of family reunions, moon-gazing, and enjoying traditional delicacies, with mooncakes being one of

Are Paper Boxes Microwave Safe?

As one of the experienced packaging consultant from Chiefcolor, a leading manufacturer of custom printed paper boxes and bags, I’ve often encountered the question: Are paper boxes microwavable?

Why Do People Love Advent Calendar Boxes?

Advent calendar boxes have become a beloved tradition for many people around the world. These festive boxes, filled with small surprises, are opened each day

Your Ultimate Guide to Acquiring Custom Boxes and Packaging

Welcome to your definitive resource for all things custom boxes and packaging! At Xiamen Chief Color Co.,Ltd, we specialize in manufacturing custom printed, branded paper packaging that elevates your products and enhances your brand image. Located in the heart of China, our factory is dedicated to producing luxury gift boxes and paper shopping bags tailored to meet the diverse needs of industries worldwide.

Explore our comprehensive guide to discover how custom boxes and packaging can transform your product presentation and drive business success. Let us help you create packaging that not only protects but also promotes your products, making them stand out in a competitive market.

Join the many businesses worldwide that trust Xiamen Chief Color for their packaging solutions and experience the difference that premium, customized packaging can make.

Table of Contents

Chapter 1

Our Custom Rigid Paper Box Production Process

| Step | Description | Quality Control (QC) |

| 1. Incoming Material | Receive raw materials like greyboard. | – |

| 2. Incoming QC (IQC) | Inspect the incoming materials for defects. | IQC – Inspect quality before use. |

| 3. Greyboard Cutting | Cut greyboard to the required size and shape. | – |

| 4. In-Process QC (IPQC) | Quality check of the cut greyboard. | IPQC – Ensure precision. |

| 5. Die-Cutting | Use die-cutting machine to shape greyboard. | – |

| 6. In-Process QC (IPQC) | Inspect die-cut pieces for defects. | IPQC – Verify precision. |

| 7. V-Groove | Cut V-groove into the greyboard for easy folding. | – |

| 8. In-Process QC (IPQC) | Quality check of the V-grooved greyboard. | IPQC – Ensure groove quality. |

| 9. Greyboard Moulding | Mould the greyboard into its final shape. | – |

| 10. In-Process QC (IPQC) | Inspect the moulded greyboard for consistency. | IPQC – Check for defects. |

| 11. Wrapping Greyboard | Wrap the greyboard with decorative paper or fabric. | – |

| 12. In-Process QC (IPQC) | Inspect the wrapping for neatness and alignment. | IPQC – Check for packaging defects. |

| 13. Assembling | Assemble the greyboard pieces into a rigid box. | – |

| 14. In-Process QC (IPQC) | Inspect the assembled box for alignment and defects. | IPQC – Check for assembly defects. |

| 15. Packing | Pack the rigid boxes for shipment. | – |

| 16. Final QC (FQC) | Final quality check before shipment. | FQC – Final quality inspection. |

| 17. Outgoing QC (OQC) | Inspect the packed boxes before shipping. | OQC – Ensure readiness for delivery. |

| 18. Shipping | Ship the boxes to customers or retailers. | – |

Chapter 2

Knowledge about Paper Packaging

2.1. How Can Finishing Techniques Elevate Your Packaging?

In the bustling world of custom printed paper boxes and bags, the difference between a product that stands out on the shelf and one that blends into the background often comes down to the finishing touches. As a director of Chiefcolor, I’ve seen firsthand how the right finishing can transform packaging from ordinary to extraordinary. Finishing techniques not only enhance the aesthetic appeal but also add a tactile quality that can significantly influence consumer perception and brand value.

But why should you care about finishing techniques? Simply put, they are the secret ingredient that can elevate your brand’s packaging to the next level, ensuring that your products capture attention in even the most competitive marketplaces.

What Are the Most Popular Finishing Techniques?

The world of packaging printing is vast and varied, offering a plethora of finishing options to make your product shine. Let’s explore some of the most sought-after finishing techniques that can give your packaging that extra edge.

- Lamination – Why Is It a Game-Changer?

Lamination adds a protective layer to your packaging, enhancing durability and resistance to wear and tear. It can be glossy, for a vibrant shine, or matte, for a sophisticated, subdued look. It can be soft-touch, for special touch-feeling. It can be anti-scratching to avoid almost all possible scratching during production. Not only does it protect, but it also adds a level of quality and refinement to your packaging. Kindly check our laminated paper bags.

- Foil Stamping – What Makes It Sparkle?

Foil stamping is the application of metallic or pigmented foil onto the surface of your packaging. It creates a stunning, eye-catching effect that can elevate your brand’s perceived value. Whether you opt for gold, silver, or any metallic shade, foil stamping is sure to make your packaging stand out.

- Embossing and Debossing – How Do They Add Dimension?

Embossing and debossing are techniques that create raised or recessed relief images and designs in paper and other materials. Embossing adds a raised detail for a tactile experience, while debossing creates an indented effect. Both can add a luxurious feel to your packaging, making it more memorable and engaging for the consumer. Embossing and debossing on paper bags and folding cartons are more prominent than on rigid boxes. It is because the different production procedures. While we have machine to create debossing unprinted logo like photo below.

- Spot UV – Why Is It a Detail Worth Considering?

Spot UV involves applying a clear, shiny coating to specific areas of your packaging. It creates a contrast between the matte or satin finish of the base material and the glossy spots, adding depth and interest to your design. Spot UV can highlight important details or create subtle design elements that catch the light and the eye.

- Varnishing – What Are Its Benefits?

Varnishing involves applying a liquid coating to a printed surface to add gloss, satin, or matte finish. It can protect against fingerprints and scuff marks, enhancing the durability of your packaging. Varnishing can also enhance the vibrancy of the colors, making your packaging more visually appealing.

How to Choose the Right Finishing Technique for Your Packaging?

Choosing the right finishing technique depends on several factors, including your brand identity, the product itself, and your target market. Consider what you want to achieve with your packaging – is it increased durability, enhanced aesthetics, or perhaps a tactile element that encourages interaction? Understanding your brand’s needs and customer preferences will guide you in selecting the most effective finishing techniques.

At Chiefcolor, we pride ourselves on our expertise in custom paper packaging solutions. Our facility is equipped with advanced printing and assembly technologies, ensuring top-quality products with versatile printing and designs. We’re here to help you make informed decisions about the best finishing techniques for your packaging needs.

Conclusion

Finishing techniques are more than just the final touches on your packaging; they’re essential elements that can significantly influence consumer perception and brand value. As the CEO of Chiefcolor, I’ve witnessed the transformative power of these techniques in making products stand out in a crowded market. Let’s work together to create packaging that not only protects your product but also tells your brand’s story in the most compelling way.

2.2 How to Choose the Right Paper for Your Packaging Needs

Choosing the right paper for your packaging needs is crucial for ensuring the durability, aesthetics, and sustainability of your products. Here’s a comprehensive guide to help you make the best choice for your custom boxes and packaging.

1. Understand Your Product Requirements

Before selecting the paper, consider the specific needs of your product:

- Weight and Size: Heavier products need sturdier paper to ensure the packaging holds up during transit.

- Fragility: Fragile items require additional cushioning and a paper that can support protective inserts.

- Brand Image: Luxury products might need premium quality paper to convey a high-end image.

2. Consider the Types of Paper

Different types of paper serve different purposes. Here are some common options:

- Kraft Paper: Known for its strength and eco-friendliness, kraft paper is ideal for sustainable packaging. It’s perfect for eco-conscious brands.

- Cardboard: A versatile option, cardboard is widely used for custom packaging boxes. It offers good protection and is easy to print on.

- Corrugated Paper: This paper type is excellent for heavy-duty packaging needs. It provides added protection due to its fluted layer.

- Specialty Papers: For luxury packaging, consider papers with special textures, finishes, or coatings that enhance the unboxing experience.

3. Evaluate Sustainability

Sustainability is a growing concern among consumers and businesses. Here’s how you can ensure your paper choice is eco-friendly:

- Recycled Content: Opt for paper with a high percentage of post-consumer waste (PCW) to reduce environmental impact.

- Biodegradability: Ensure the paper is biodegradable and can decompose without harming the environment.

- Certifications: Look for certifications like FSC (Forest Stewardship Council) or PEFC (Programme for the Endorsement of Forest Certification) that guarantee sustainable sourcing.

4. Printing and Finishing Techniques

The right paper should complement your printing and finishing techniques:

- Printability: Ensure the paper type you choose allows for high-quality printing. Smooth surfaces are ideal for detailed graphics.

- Finishes: Consider finishes like matte, gloss, or UV coating that can enhance the look and feel of your packaging.

- Embossing and Foil Stamping: If you want to add a touch of luxury, ensure the paper can handle embossing, debossing, or foil stamping.

5. Cost Considerations

Budget is a significant factor in choosing the right paper:

- Bulk Orders: Buying in bulk can reduce costs. Ensure the paper type you choose is available in the quantities you need.

- Supplier Reliability: Work with reputable suppliers who can provide consistent quality and timely deliveries.

By carefully considering these factors, you can choose the right paper for your custom boxes and packaging, ensuring it meets both your practical needs and brand values.

2.3 Trends in Sustainable Packaging

Sustainable packaging is more than a trend; it’s a necessity for businesses aiming to reduce their environmental impact and appeal to eco-conscious consumers. Here are the latest trends in sustainable packaging, particularly in the realm of custom packaging boxes and luxury paper bags factory production.

1. Increased Use of Recycled Materials

One of the most significant trends is the use of recycled materials:

- Post-Consumer Waste (PCW): Brands are increasingly opting for paper with high PCW content. This not only reduces waste but also conserves natural resources.Please refer to the Charpter 1 series.

- Upcycled Materials: Beyond traditional recycling, upcycling transforms waste materials into new products, adding value and reducing environmental footprint.

2. Biodegradable and Compostable Packaging

With the growing concern over plastic pollution, biodegradable and compostable packaging solutions are gaining traction:

- Biodegradable Paper: Papers that decompose naturally are becoming popular, particularly for luxury paper bags and custom packaging boxes.

- Compostable Packaging: These materials break down into non-toxic components, enhancing soil health and reducing landfill waste.

3. Minimalist Packaging

Less is more when it comes to sustainable packaging:

- Eco-Friendly Design: Minimalist designs reduce material use and waste. Simple, elegant packaging can still deliver a luxurious feel without excess.

- Efficient Use of Space: Optimizing packaging design to fit products perfectly reduces the need for additional filler materials, lowering overall material usage.

4. Innovative Materials

Innovation in materials is driving sustainability:

- Plant-Based Plastics: Derived from renewable sources like corn or sugarcane, these plastics are biodegradable and reduce dependency on fossil fuels.

- Mushroom Packaging: Made from agricultural waste and mycelium, this packaging is fully biodegradable and compostable.

- Seaweed-Based Materials: These are emerging as sustainable alternatives for traditional packaging materials, offering biodegradability and reducing marine pollution.

5. Sustainable Printing Techniques

Printing methods have also evolved to support sustainability:

- Soy-Based Inks: These inks are less toxic and more biodegradable than traditional petroleum-based inks.

- Water-Based Coatings: These coatings provide a sustainable alternative to chemical-based coatings, ensuring packaging is environmentally friendly.

6. Consumer Education and Transparency

Brands are recognizing the importance of educating consumers about their sustainable practices:

- Clear Labeling: Transparency in labeling helps consumers make informed choices. Labels that highlight recycled content, biodegradability, and eco-certifications build trust.

- Storytelling: Sharing the journey of sustainability efforts resonates with consumers. Highlighting the sustainable choices in your packaging can enhance brand loyalty.

By staying abreast of these trends, businesses can not only meet consumer demand for sustainable products but also contribute to a healthier planet. Implementing these trends in your custom packaging boxes and luxury paper bags factory production can set your brand apart as a leader in sustainability.

Chapter 3

How Can We Reduce Carbon Emissions from Our Paper Product Packaging?

3.1. Strategies for Reducing Carbon Footprint in Paper Production

1. Source Sustainable Materials

- Use Recycled Content: Incorporating post-consumer waste (PCW) and recycled materials reduces the demand for virgin fibers, which in turn decreases deforestation and its associated emissions.

- Choose Certified Paper: Opt for paper sourced from forests certified by organizations like the Forest Stewardship Council (FSC). This ensures that the paper comes from responsibly managed forests that provide environmental, social, and economic benefits.

2. Optimize Design and Production

- Design for Efficiency: Minimize material use by designing packaging that fits the product perfectly, reducing waste and the energy used in production.

- Reduce Production Waste: Implement lean manufacturing techniques to streamline production processes, reducing waste and improving efficiency.

3. Adopt Energy-Efficient Technologies

- Upgrade to Energy-Efficient Equipment: Use the latest technology in printing and production equipment that consumes less energy.

- Utilize Renewable Energy: Transition to renewable energy sources, such as solar or wind power, for manufacturing processes to cut down on fossil fuel consumption.

4. Enhance Transportation Efficiency

- Optimize Logistics: Consolidate shipments and optimize routes to reduce fuel consumption. Using electric or hybrid vehicles for transportation can also lower emissions.

- Localize Production and Supplies: Whenever possible, source materials from local suppliers and produce closer to the end consumer to minimize transportation distances.

5. Implement Waste Management Practices

- Recycling and Reuse: Establish programs for recycling scrap and unused materials in the production process. Encourage customers to recycle by providing clear instructions and promoting the recyclability of packaging.

- Composting: For biodegradable packaging options, promote composting as a way to return nutrients to the soil, reducing the need for synthetic fertilizers and their associated greenhouse gas emissions.

6. Invest in Carbon Offsetting

- Support Reforestation Projects: Invest in reforestation or forest conservation projects that absorb CO2 from the atmosphere, offsetting the emissions produced by the packaging.

- Engage in Carbon Offset Programs: Purchase carbon credits to compensate for the emissions you can’t eliminate. This supports renewable energy, energy efficiency, and reforestation projects.

7. Educate and Collaborate

- Educate Stakeholders: Inform customers, suppliers, and employees about the importance of reducing carbon emissions and how they can contribute.

- Collaborate on Sustainability: Work with other businesses, industry groups, and non-profits to share best practices and promote industry-wide efforts to reduce carbon emissions.

By implementing these strategies, we can significantly reduce the carbon footprint of our paper product packaging. It’s not only beneficial for the environment but also enhances our brand’s value and appeal to environmentally conscious consumers.

3.2. The Role of Recycled Materials in Carbon Reduction

- Incorporating Recycled Content: Using recycled paper reduces the demand for virgin materials and decreases the energy required for production. Custom boxes and packaging made from post-consumer waste (PCW) can significantly lower carbon emissions.

- Closed-Loop Recycling: Implementing a closed-loop recycling system within the production facility ensures that waste paper is continually recycled, minimizing the need for new raw materials and reducing overall emissions.

- Promoting Recycling: Encourage customers to recycle by providing clear instructions on the packaging. This helps in extending the life cycle of paper products and reduces waste sent to landfills.

3.3. Energy-Efficient Manufacturing Processes

- Upgrading Machinery: Invest in modern, energy-efficient machinery. Newer equipment typically consumes less energy and operates more efficiently than older models.

- Process Optimization: Streamline production processes to reduce energy consumption. Techniques such as just-in-time manufacturing can minimize idle time and energy waste.

- Heat Recovery Systems: Install heat recovery systems to capture and reuse waste heat generated during production. This can significantly lower the energy required for heating and cooling in the facility.

- LED Lighting: Switch to LED lighting in production areas and offices. LEDs use less energy and have a longer lifespan compared to traditional lighting solutions.

3.4. Certifications and Standards for Low-Carbon Packaging

- Carbon Trust Standard: Achieving the Carbon Trust Standard demonstrates a company’s commitment to measuring, managing, and reducing carbon emissions. It provides third-party validation of a company’s efforts in sustainability.

- ISO 14001 Certification: ISO 14001 is an international standard for environmental management systems. Certification indicates that a company has implemented effective processes to reduce its environmental impact, including carbon emissions.

- LEED Certification: For facilities, obtaining LEED (Leadership in Energy and Environmental Design) certification ensures that the building meets stringent environmental standards, including energy efficiency and reduced carbon footprint.

- Cradle to Cradle Certification: This certification assesses the sustainability of products through their entire life cycle. It evaluates material health, material reuse, renewable energy, water stewardship, and social fairness.

By adopting these strategies and certifications, print and packaging companies, including rigid boxes suppliers and luxury paper bags factories, can significantly reduce their carbon emissions. Implementing these practices not only helps the environment but also meets the growing consumer demand for sustainable, eco-friendly packaging solutions.

Chapter 4

What Conditions Should a High-Quality Paper Product Packaging Company Have?

As the Marketing Director of Chiefcolor, a premier provider of custom printed paper boxes and paper bags, I understand the essential conditions that define a high-quality paper product packaging company. Here’s an in-depth look at the crucial aspects you should consider when choosing a packaging partner.

4.1. Certifications and Standards to Look For

Certifications and standards are vital indicators of a company’s commitment to quality and ethical practices. Here are the key certifications and standards to consider:

- SA8000: This certification focuses on social accountability. It ensures that the company adheres to fair labor practices. At Chiefcolor, we take pride in our SA8000 certification, reflecting our commitment to ethical working conditions.

- ISO9001: This standard is crucial for quality management systems. It indicates that the company maintains high standards in its production processes. ISO9001 certification means consistent quality in custom boxes and packaging.

- ISO14001: This certification pertains to environmental management systems. It shows the company’s dedication to minimizing its environmental impact. At Chiefcolor, our ISO14001 certification demonstrates our commitment to sustainability.

- FSC Certification: The Forest Stewardship Council certification ensures that paper products come from responsibly managed forests. It’s essential for businesses that prioritize eco-friendly practices. Our FSC certification guarantees that our products support sustainable forestry.

These certifications not only ensure quality and ethical standards but also build trust with clients and consumers.

4.2. Innovation and Technology in Packaging

Innovation and technology are at the heart of a successful packaging company. Here’s what to look for:

- Advanced Printing Techniques: The use of state-of-the-art printing technologies like digital printing, offset printing, and flexographic printing ensures high-quality, vibrant, and precise prints. These techniques are essential for producing top-notch custom packaging boxes.

- Automated Assembly Facilities: Automation enhances efficiency and consistency. At Chiefcolor, we have three advanced facilities for automatically assembling paper bags and five for paper boxes. This reduces errors and speeds up production, ensuring timely delivery of custom packaging solutions.

- Innovative Materials: Companies that invest in innovative materials, such as biodegradable or recycled papers, demonstrate a commitment to sustainability. Innovative materials also offer unique textures and finishes for customised packaging boxes.

- Customization Capabilities: The ability to offer customized solutions, from bespoke designs to unique finishes, is a testament to a company’s technological prowess and flexibility. At Chiefcolor, we provide a wide range of customization options to meet diverse client needs.

4.3. Customer Service and Customization Options

Exceptional customer service is a cornerstone of a high-quality packaging company. Here’s what to expect:

- Personalized Service: The company should offer personalized service tailored to your specific needs. This includes understanding your brand, product requirements, and providing bespoke solutions. At Chiefcolor, we pride ourselves on our personalized approach to customer service.

- Clear Communication: Efficient communication is vital. Sales representatives should be responsive, knowledgeable, and able to provide clear and timely information. This helps in avoiding misunderstandings and ensures smooth transactions.

- Customization Options: Look for a company that offers a wide range of customization options. This includes various sizes, shapes, materials, and finishing techniques like embossing, foil stamping, and UV coating. Our extensive customization options ensure that your custom boxes and packaging meet your exact specifications.

- After-Sales Support: Good after-sales support ensures that any issues are promptly addressed and resolved, enhancing overall satisfaction. We offer robust after-sales support to ensure complete client satisfaction.

4.4. Sustainability Practices and Environmental Responsibility

Sustainability is not just a trend but a necessity in today’s business environment. A high-quality paper product packaging company should prioritize environmental responsibility.

- Eco-Friendly Materials: The use of recycled and biodegradable materials is essential. At Chiefcolor, we emphasize using high PCW (post-consumer waste) content in our products. This reduces environmental impact and supports sustainability.

- Sustainable Practices: Look for companies that implement sustainable practices in their operations. This includes energy-efficient manufacturing processes and waste reduction strategies. Our ISO14001 certification is a testament to our commitment to sustainable practices.

- Certifications: Certifications like FSC and ISO14001 are indicators of a company’s commitment to sustainability. These certifications ensure that the company’s practices align with global standards for environmental responsibility.

- Transparency: The company should be transparent about its sustainability practices, providing clear information about the materials used and the steps taken to reduce environmental impact. At Chiefcolor, we are committed to transparency in all our operations.

Get A Free Quote

Contact us to get a free quote and more expertise about custom boxes and packaging. Your project will meet a right solution with Chiefcolor.

Boost Your Business with Custom Boxes and Packaging

Tell Us What You Need

Tell us as specific as possible of your needs, provide the drawing, reference picture and share your idea.

Get Solution & Quote

We will work on the best solution according to your requirement and drawing, the specific quote will be provided within 24 hours.

Sample & Mock Up

We will offer free white sample for testing and developing on your project.